Research Degree Scholarships in Engineering

Engineering Scholarships

The School of Computing and Engineering offers various fee waiver and scholarship opportunities for Master’s by Research and PhD applicants. All scholarship schemes are assessed on a competitive basis judged on academic record, aptitude for research, understanding of the proposed research project, knowledge of the background/literature, research skills and motivation. If you are shortlisted then you will be invited to an interview with the School Fee Waiver Panel (conducted remotely via video conferencing as appropriate).

Prior to application, you should identify a potential supervisor in the School who is prepared to support your application for a fee waiver or scholarship. This can be done by discovering the research projects advertised on Coursefinder or, if you wish to explore further opportunities or propose your own project, then you will need to approach potential supervisors who can be identified through their Pure profiles. They will also be able to advise you on completing your application.

When you are ready to apply, please complete the online application form. If you wish to be considered for a School Fee Waiver or a Vice Chancellor’s Scholarship, please clearly indicate this on your application.

Applications deadlines for School Fee Waiver and Vice Chancellor’s Scholarship schemes:

|

Research start date |

Application deadline |

|

January 2023 |

21 October 2022 |

| April 2023 |

27 January 2023 |

| September/October 2023 |

9 June 2023 |

School of Computing and Engineering Scholarships

School of Computing and Engineering Scholarships are awarded for 25%, 50%, 75% or 100% of tuition fees for the standard registration period only.

Candidates must have a:

* First-class honours degree (or equivalent);

* Taught Master’s with distinction; or

* Master’s by Research with a recommendation from their supervisor from that time

If you are due to graduate in the current academic year, any offer will be conditional on your final degree outcome.

If your first language is not English, you will need to meet the minimum requirements of an English Language qualification. For a School of Computing and Engineering Scholarship, the minimum for IELTS is 6.5 overall (with no element lower than 5.5) or equivalent will be considered acceptable. Read more about the University’s entry requirements for students outside of the UK on our Where are you from information pages.

Reapplications for a scholarship within the School of Computing and Engineering following a previous unsuccessful application will not be considered.

Engineering Scholarships

Predictive models for S&C monitoring

Scholarship - Development of predictive models for S&C monitoring and predictive maintenance

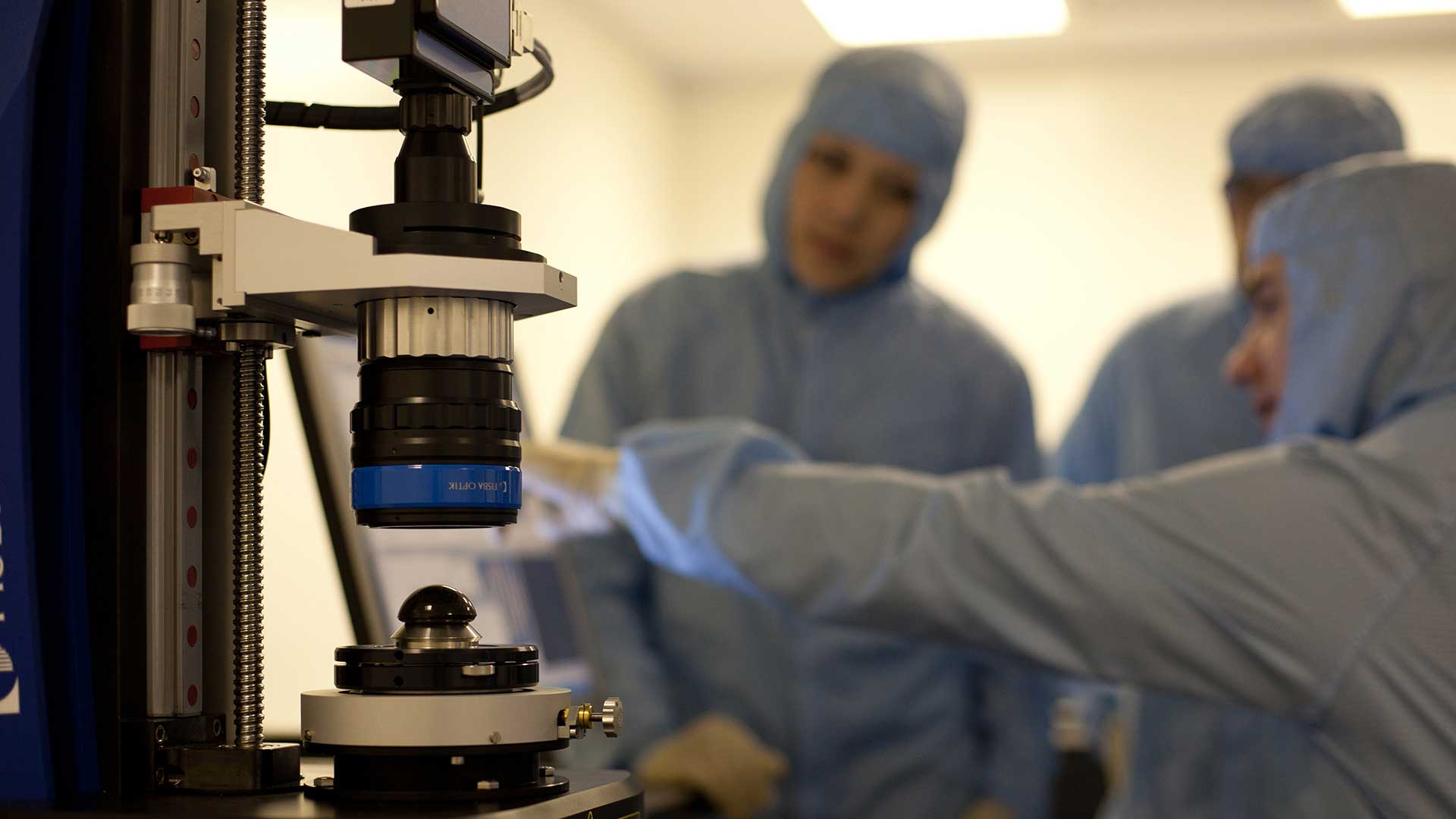

Under the Skin of Ultra-Precision Manufacturing

Tuition fee waiver, bursary of £15,609

Vice Chancellor’s Scholarships

A Vice Chancellor’s Scholarship covers 100% of the tuition fees.

School of Computing and Engineering Scholarships

Fee waivers are awarded for 25%, 50%, 75% or 100% of tuition fees

Vice Chancellor’s Scholarships

A Vice Chancellor’s Scholarship covers 100% of the tuition fees for the standard registration period only.

Candidates must have graduated from the University of Huddersfield in the last three years with a:

- First-class honours degree;

- Taught Master’s with distinction; or

- Master’s by Research with a recommendation from their supervisor from that time

If you are due to graduate in the current academic year, any offer will be conditional on your final degree outcome.

Reapplications for Vice Chancellor's Scholarship within the School of Computing and Engineering following a previous unsuccessful application will not be considered.

Train Brake Optimisation in Low Adhesion Conditions

|

Supervisory Team |

Main Supervisor |

|

|

Co-Supervisor |

||

|

|

|

|

|

Research Centre |

||

|

Funding available |

|

|

|

Deadline for applications |

21 October 2022 |

|

|

For application process see link |

||

|

Start Date |

January 2023 |

|

Project background:

The ability of a train to brake effectively in low adhesion conditions is a consequence of the interaction between many train components; wheelsets, wheel-rail contact patch adhesion, dynamic brakes, friction brakes, sanders and brake controllers. In the presence of low adhesion conditions, the reduced accelerations achieved during traction and decelerations during braking, can significantly impact on journey times leading to delays across the network.

Project aim:

To optimise the train brake function at low adhesion conditions to avoid wheel damage, minimise braking distance, and minimise the power consumption.

Project objectives:

- Develop a model for the current brake systems and validate it using experimental data.

- Propose and develop control system to overcome the current brake system problems at low adhesion conditions such as (train speed estimators, adhesion prediction).

- Propose a robust control strategy for the Wheel Slide Protection (WSP) to enhance the braking system performance.

- Study the feasibility of using electrical system instead of pneumatic system in the train brake system (performance and safety issues).

- Build Hardware in the Loop rig to test the developed control strategies.

Candidate

- Must have a degree in Mechanical/Electrical/Electronic Engineering (or equivalent qualification).

- MSc in relevant field is highly desirable.

- Good background at maths and control systems.

- Good experience in modelling and simulation of mechanical, electrical, and electromechanical systems.

- Good knowledge of MATLAB/Simulink software. Experience in other programming languages is desirable (C, C++, Python, ...etc.).

- Experience in embedded systems (microcontroller) and real-time systems is highly desirable.

Starting date: October 2022

Under the Skin of Ultra-Precision Manufacturing

|

Supervisory Team |

Main Supervisor |

Prof David Walker |

|

Co-Supervisor |

Prof Rakesh Mishra |

|

|

|

|

|

|

Research Centre |

Laboratory for Ultra-precision Surfaces, Daresbury site Part of the Huddersfield Centre for Precision Technologies |

|

|

Eligibility |

Students who are eligible for UK home tuition fees, and with a relevant first or upper-second class degree. |

|

|

Funding available |

Tuition fee waiver, bursary of £15,609 |

|

|

Deadline for applications |

21 October 2022 |

|

|

For application process see link

Informal enquiries and applications to:- |

https://courses.hud.ac.uk/2021-22/full-time/postgraduate/engineering-phd/#topic:00006190_2591 |

|

|

Start Date |

January 2022 |

|

Project Summery

This studentship will contribute to exciting research in advanced robotic manufacture of ultra-precision surfaces on glass materials. These are required for numerous applications in science, medicine and industry. Fine surface processing involves “rubbing” rather than cutting, and is still poorly understood at the fundamental level. The studentship is part of a £1.2m EPSRC-funded project involving four partners to deepen that understanding, by exploring challenging science at the interface between what happens at the atomic scale (molecular dynamics) together with the macroscopic interactions between fluid abrasive media and the tool and glass (computational fluid dynamics). The aim is, for the first time, to combine both types of computer modelling in a comprehensive model of the process, informed by controlled experiments with extensive real-time process-monitoring. The end-game is to combine modelling results with active control to keep processes ‘on track’, reducing manufacturing cost, time and defect-rate.

Background to the research area

The area of work concerns manufacture of precise optics such as lenses and mirrors that underpin a huge range of applications. These include remote-sensing from space, astronomy, photolithography of semiconductor chips, laser-physics, medical diagnostics, security & defense. In the future, energy from laser-fusion may require huge numbers of optics, with repeated refurbishment due to laser damage. A topical application for mass-produced optics is autonomous electric vehicles, requiring cameras, sensors and advanced lighting.

Today, corrective ultra-precise finishing of most glasses and similar materials relies on abrasive-slurry processes, due to sheer practicality and versatility. Given the underlying complexities, results are imperfectly predictable (even on CNC machines or robots), requiring repeated and costly iterations of polish ó metrology. Sometimes, surface quality regresses for no obvious reason, and unexpected artefacts are common. In attempting to resolve this, there is one key factor over which we have neither knowledge nor control:- the micro and macroscopic details of how abrasive slurry traverses the work-piece/tool interface, particularly for complex surfaces. Flow can be laminar or turbulent, slurry-starvation can occur, and at the other extreme, aqua-planing. These all affect speeds/trajectories of the individual slurry particles carried by the liquid medium through the interface with the part, and so the chemical and mechanical interactions with the glass. These in turn drive the instantaneous material removal rates and their inherent variability.

EPSRC has awarded major research grants to a Consortium led by Huddersfield’s Laboratory for Ultra Precision Surfaces at Daresbury. The other partners are the Computational Fluid Dynamics (CFD) group on-campus at Huddersfield led by Prof Mishra, the Molecular Dynamics (MD) group at Liverpool John Moores University, a glass expert at Sheffield Hallam University and the Hartree Supercomputer Centre at Daresbury. The objective is to create the world’s first multi-scale model of ultra-precision abrasive processes, demonstrating predictive capabilities that promise to be the key to improve the predictability and quality of robotic surface-finishing processes. The broad scope of the overall EPSRC project involves:-

Context for the student research – the new EPSRC-funded project

- Mechanistic understanding of the physical-chemical contributions to glass polishing

- CFD modelling to predict microscopic slurry-particle velocities and trajectories, as input to:

- MD modelling, to predict removal-rates at nano-scales

- Combined in development of a macroscopic model to predict removal in real-time

- Accommodating real-life processing-geometries (flat – to – complex surfaces)

- Supported by gathering extensive real-time process-data (forces, torques, acoustics, abrasive-slurry conditions) and post-process data (surface-metrology) on a range of sample parts processed under different conditions.

- With machine learning algorithms applied to the accumulated data-base to complement and reinforce modelling

Opportunities for the student’s research contribution

We are now seeking a student to work under the University of Huddersfield within the multi-institute, multi-disciplinary project team. The exact role of the student is very flexible, but needs to be an area of research that is relevant and useful to Huddersfield’s work on the project, of interest to the student, and within the student’s capabilities.

The preferred – but not the only acceptable – area of work would focus on the exciting opportunity presented by the interface between i) hands-on experimental work, data capture & interpretation, and ii) helping to develop and verify a process-model that can predict material removal, given real-time sensor data, modelling results and artificial intelligence.

Qualifications and background

We are considering candidates for a funded PhD Studentship, which is open to individuals meeting academic requirements who are eligible for UK home tuition fees. There is considerable flexibility in the specific area(s) in which the successful candidate will contribute to the EPSRC project described above, which in turn will influence the appropriate qualifications and experience. Overall, the project would suit a Mechanical Engineering or Physics graduate with computational, modelling or experimental skills. Degree course-content in Materials Science would be advantageous.

The project will include a significant element of adventure, and the successful candidate will be prepared to tackle unexpected problems, be inventive and willing to stretch beyond past fields of experience. Good written and verbal communication skills in English are essential. Computer literacy is a requirement, alongside a willingness to learn specific modelling codes depending on the detailed project. For the preferred area of work (as above) general competence in experimental technique is required, and training will be provided for safe and effective use of CNC and robot polishing platforms, supporting software and metrology instrumentation.

The studentship will be physically located within the stimulating environment of the National SciTech Daresbury Science and Innovation Campus (near Warrington). This where the Huddersfield Laboratory for Ultra Precision Surfaces is based, a few minutes’ walk from the Hartree Supercomputer Centre.

PhD Studentship:

Coded Excitation Methodologies for Ultrasonic Testing Techniques, Exhibiting Poor Signal to Noise Performance

The University of Huddersfield, School of Computing and Engineering, National Structural Integrity Research Centre (NSIRC), TWI and Lloyd’s Register Foundation

Qualification Type: PhD

Location: Huddersfield and Port Talbot, UK

Funding for: Students worldwide

Funding amount: £16k p .a.

Hours: Full time, 3 years plus 12 months writing up

(please note that no funding is available for the writing up period)

Details 3 years full time research, covering a tax-free bursary (stipend) at £16k. Tuition fees will be waived. This project is funded by Lloyd’s Register Foundation, TWI and the University of Huddersfield. PhD registration is at the University of Huddersfield.

Eligibility (entry requirements): First Class or Upper Second Class Honours degree or equivalent in relevant subject areas

Supervisory Team:

- Miles Weston, Technology Consultant at TWI

- Len Gelman, Chair in Signal Processing and Condition Monitoring, the University of Huddersfield

- Andrew Ball, Professor of Diagnostic Engineering, Pro Vice-Chancellor, the University of Huddersfield

Project description

UT techniques suffer from poor SNR and low penetration when:

- the material under inspection has non-ideal acoustic properties (e. g. plastics, composites, austenitic)

- the sensors to generate and receive signals due to environmental limitations are:

- using transduction materials with sub-par properties (high temperature) or

- limited in their maximum operating voltage (explosive environments)

- the frequency of the acoustic wave requires to be increased

- Acoustic beam shape

- Beam propagation

- Acoustic signal penetration

- Signal to noise ratio of processed signals

- Spatial resolution

- Waveguide requirements

With UT we do include single element techniques, multi element phased array (PAUT) and synthetic beamforming techniques (FMC/TFM), along with guided acoustic wave techniques (LRUT/GUW). Work performed in TWI has already shown that coded excitation is a promising set of methodologies that can overcome all the above cases that seem disparate at first glance.

The first stage of this research would be to theoretically and experimentally compare coded excitation methodologies with respect to at least:

Using tuned negative square pulse and Hann windowed sinusoidal pulses as the comparison basis.

The theoretical work will include:

- Tuned coded waveform generation

- Ultrasonic transducer transfer function estimation

- Investigation of the applicability of semi-analytical acoustic wave propagation models with coded excitations

- FEA dynamic wave propagation simulations

Semi-analytical and FEA tools along with example models already exist in TWI.

The experimental work will include:

- Experimental definition of ultrasonic transducer transfer function.

- PWM transducer drive to generate controllable sinusoidal signals

- identifying electronic circuit limitations

- Receive signal processing (matching filters, auto-cross correlation etc.)

- Comparative feature extraction

- Automation of experimental setups

The second stage of this research is to experimentally evaluate the usefulness of coded excitation on a series of engineering applications, where UT is currently not possible or is severely limited.

We are looking for candidates with an enthusiasm for research, multidisciplinary collaboration and tackling challenging problems through teamwork. Applicants should be of a high quality and exceptionally motivated. Experience with ultrasound non-destructive testing and essential experience in programming in Matlab would be advantages.

This is an exciting opportunity for a pro-active student to join TWI Technology Centre (Wales) and the Centre for Efficiency and Performance Engineering (CEPE), led by Professor Len Gelman, a holder of two Rolls Royce Awards for Innovation.

TWI Technology Centre (Wales) specialises in the development and application of state-of-the-art non-destructive testing (NDT) methods. Through applied research and development in response to requests for assistance from member companies, we provide real-world solutions to inspection challenges across a broad range of industries.

The CEPE has a strong record in applied research in the academic and industrial sectors. Application areas, related to the post, include vibration monitoring of complex electro-mechanical systems, advanced non-stationary signal processing, pattern recognition and multi-sensor fusion. These are applied to multiple industries, including power generation, automotive, aerospace and oil and gas.

If you wish to discuss any details of the project informally, please contact: Miles Weston, email: Miles.Weston@twi.co.uk and Prof. Len Gelman, email: l.gelman@hud.ac.uk

Applications should include: Curriculum Vitae, two reference letters and degree transcripts to date and certificates of all relevant academic and/or any professional qualifications.

Please note: if you do not attach all the relevant documentation prior to the closing date your application will not be considered.

Deadline for applications is 5 September 2022 - please email your application to l.gelman@hud.ac.uk

Start date: January 2023

Development of predictive models for S&C monitoring and predictive maintenance

Background

Switches and crossings are the most complex part of the railway track network and they contribute a disproportionate amount to track renewal and maintenance expenditure. Concerning crossings, Network Rail identified in its challenges statements that the estimated annual costs for cast crossing replacements and their attributed delay penalties equate to over £24M per year. Root causes are multiple, relating to support conditions (poor ballast quality, stiffness variation, pad conditions, load amplification) and fundamental design of the wheel-rail interface leading to dip angle and impact load. However, this is exacerbated by poor data management with regards to the evolution of the asset: lack of remote conditions monitoring solutions, incomplete knowledge of asset and lack of degradation history. With the development of accurate and sophisticated physics-based models capturing the performance of these assets, the increasing availability and deployment of sensors as well as the digitalisation agenda of the railway industry, there is scope to make these complex assets more intelligent to better tailor their maintenance needs.

Outline & focus

The project will focus on further developing the advanced modelling capabilities already available at the University of Huddersfield - Institute of Railway Research for predicting the full vehicle-turnout dynamic behaviour, by bringing together different field monitoring data (from NR data to specific spot measurement using accelerometers, hammer testing and other sensors on specific assets) and advanced FEM/MBS modelling techniques of vehicle-track interaction in S&C. Measurement data will support the further validation of those models and targeted site for which multiple data source are available will be identified to support this activity. The validated high accuracy models will support the understanding and long-term prediction of damage mechanisms in S&C and in turn support the definition of simpler physics models and sensors requirements for predictive maintenance.

Objectives

- Carrying out a literature review on numerical modelling of vehicle-turnout interaction and appraisal of existing available models.

- Drafting a development plan for a suitable numerical solution of vehicle-turnout dynamics modelling using FEM and MBS technology

- Identifying field monitoring opportunities and other data source for monitoring states of S&C.

- Carrying out field monitoring, data processing and model validation (transient dynamic prediction as well as long term damage predictions)

- Proposing and developing simpler physics models capturing long terms trends and making recommendations in terms of sensor technology requirements to feed those models.

Candidate

Must have a degree in Mechanical Engineering (or equivalent qualification).

MSc in relevant field is highly desirable.

Good background at maths and physics.

Good experience in modelling and simulation of mechanical or electromechanical systems.

Good knowledge of MATLAB, FEA and MBS simulation software.

Experience in other programming languages is desirable (C, C++, Python, ...etc.).

Experience in practical laboratory/field experimental methods and use of a range of sensors (e.g. accelerometers) and datalogging equipment is highly desirable.

Starting date - January 2023

Deadline for application - 21 October 2022

Funding available

Home student: £15.6k pa stipend (over 3.5 years with yearly increment) + fees

Overseas student: £15.6k pa stipend (over 3.5 years with yearly increment) + 17k pa fees (5k paid by the sponsor and 12k to be paid by the applicant)

Supervision

Main supervisor: Prof Yann Bezin

Co-supervisor: Pedro Jorge and Hossein Otorabad

Industrial supervisor: Matt Crompton (Network Rail)